Old Oak Common

RJ Power Rail has completed its electrical and mechanical decommissioning contract works on behalf of Principal Contractor Colas Rail, for the Stage 2 and 3 decommissioning of Old Oak Common Depot. The scope also included civil engineering activities such as Under Road Crossings (URX’s), Ducting and Troughing Route works and Protective Barrier installation works.

As part of Phase 1 of the HS2 rail network, a new interchange station is being constructed at Old Oak Common to provide a rapid and convenient access for passengers between High Speed 2 (HS2), Crossrail and the Great Western Main Line (GWML) services.

The site, which is occupied by both Great Western (GWR) and Heathrow Express (HEx), required decommissioning and was a critical piece of work for the overall HS2 programme in order to facilitate the commencement of the HS2 enabling works associated with the GWML.

The works included four Sub-Stations:

- Sub-Station B1

- Sub-Station B5

- Sub-Station T

- Sub-Station S

and a number of 6.6kV HV Feeders:

- Cable 43A

- Cable 43C

- Cable 44

- Cable 45

In order to achieve the space requirements for the OOC interchange station, the relocation of GWR and HEx services from the existing Old Oak Common Depot was necessary.

A number of challenges were faced, however, RJ Power Rail’s capabilities in the multi-disciplined and HV market, combined with its ability to offer additional works and engineering input made it the ideal contractor for this project. With vast experience as a Tier-2 contractor for major schemes, RJ Power Rail offered a consistent, reliable and flexible service, through exceptional expertise and proven project delivery.

RJ Power Rail commenced its works in December 2018, decommissioning the Depot in a number of stages, in order to ensure that operations were maintained. RJ Power Rail’s works covered Stages 2 and 3 (which in the end were combined) and successfully completed all of its works in May 2019.

The successful delivery of the project enabled the undertaking of the next stage of HS2 works – a project with the promise of developing a faster and more efficient rail network for the UK.

“RJ Power Rail’s project and engineering teams pulled out all stops to ensure this electrification support project was delivered on time and to specification. In addition to this, the team worked collaboratively with us to support changes in design and perform additional works that will benefit the wider scheme.

“I would like to thank all involved for their efforts in this completing this project.”

Joseph Smales, Project Manager – Infrastructure, Colas Rail

Project Deliverables

RJ Power Rail’s work scope included providing all necessary stakeholder management and permits to work for the project and consisted of the following deliverables. All works were fully tested and commissioned and involved the provision of all necessary hand back and handover documentation including certificates and redline drawings for as-built purposes:

Mechanical Works

- Decommissioning and isolation of gas supplies within depot, including purging pipes and cutting sections of pipes

- Decommissioning and isolating of the lubricating oil, diesel oil, and coolant pipe supplies within the depot, including draining down reservoir tanks and pipes and also cutting pipes

- Isolation of water supplies to the water tower at water meters and supply to the HST shed

- Isolation of depot fire hydrant pipework system back to the first fire hydrant located at depot entrance ensuring this hydrant remains operational

- Decommissioning of compressed air supply and associated equipment in HST shed

- Diversion of the water supply to the Heathrow Express train wash shed – this also included:

Civil Engineering and groundworks for the relocation of the water meter covering:

- Under Road Crossing (URX) complete, including excavation and reinstatement

- Installation of access chambers and buried routes using 150mm ducting

- Installation of buried routes using C/1/9 trough

- Installation of C/1/9 surface laid trough routes

- Installation of protective barriers

Electrical Works

- Isolation and decommission of LV supplies to multiple equipment located in all parts of the depot.

- Decommissioning of LV supply transformers

- Diversion and installation of existing and new LV cables to points heating control cubicles and the Heathrow Express train wash shed

- Installation of new lighting columns, associated cabling, column bases and route works, including concrete troughing and buried ducting

- Relocation of points heating control panel, track side boxes, 110v transformers. Installation of concrete bases associated cabling and route works

- Decommissioning and recovery of points heating equipment for track plain lining

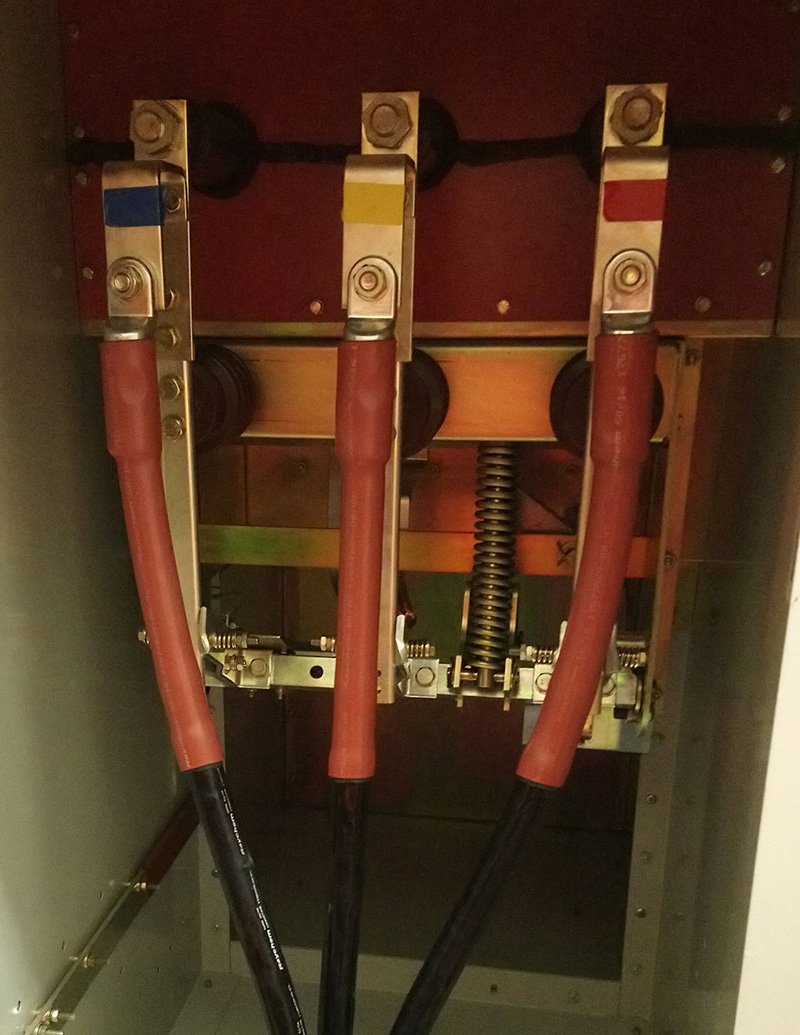

- Isolation and diversion of the high voltage 6.6kv ring main circuit

- Installation of new HV cable, jointing of HV cable, testing and commissioning

- Spiking and recovery of redundant HV cable

- Isolation and slew/diversion of the HV 25kv OHL feeder cable into new route

This also included the following:

Civil Engineering Works

- Installation of raised Armco GRP trough and concrete trough route for containment of 6.6kv ring main and 25kv

Challenges & Solutions

Site Logistics

During the works, careful logistical traffic management was implemented by RJ Power Rail, with all deliveries being pre-planned and sequenced in accordance with a Traffic Management Plan. All vehicles accessing the site had to be in line with the directives given by the site Traffic Marshals.

All plant/pedestrian interfaces had to be managed around the nominated site storage and parking areas too. To combat this, segregated walking zones were created and a Banksman was present during the transportation and lifting into position of all materials for the works.

Stakeholder Interface

RJ Power Rail faced challenges with the timescale of this project due to the number of different project interfaces during the course of these works. With the works being of a multi-disciplinary nature and with multiple contractors needing to negotiate access arrangements, RJ Power Rail’s team needed to be extremely flexible and work collaboratively with others, when approaching and delivering key milestones in their programme.

This liaison was particularly important, as the electrical and water supply services were still required to be available within the depot. RJ Power Rail carefully interfaced with the Colas Rail team, Heathrow Express and GWR in order to programme and plan a phased decommissioning and diversion of the services, so as to ensure as little disruption as possible.

Unknown Buried Services

The project was further challenged, when it was found that the civils design through the depot access road was not achievable, due to the presence of a large amount of unknown buried services and the radius bend of the existing waterpipe.

RJ Power Rail proposed to move the excavation to one side of the access road, away from the middle of the road, allowing the road to remain partially open, which also gave enough distance from the existing buried surfaces and allowed the excavation to run straight rather than stagger around other buried services. This in turn made the installation of the water pipe easier, due to the fact that it could only change direction by an angle of either 45° or 90°.

Roadway Construction

The road plates were required to sit flush to the road to eliminate tripping hazards. To achieve this the design showed a 45mm recess to be broken out either side of the excavation, with a 20mm cementitious grout laid for the steel road plates to sit on. Due to the composite construction of the road this proved to be unachievable due to the amount of re-bar present.

RJ Power Rail provided a solution that involved excavating the full width of the road plates, applying shuttering to either side of the trench width and then building back up to the recess level, in order to achieve a flush road plate.

The design also showed the excavation connecting onto an existing oil/diesel pipe trench, however, during the works, the trench was found to be full of diesel and oil.

RJ Power Rail resolved this by core drilling through the walls of the existing trench to allow the waterpipe and 6.6kv HV cables to divert over the diesel and oil. This enabled the excavation to continue and run parallel with the oil trench, until such a time when it could be diverted and then connected back to the originally designed route.

6.6kv Ring Main and 25kv HV System

The diversion of the 6.6kv ring main and 25kv OHL high voltage system was an extremely challenging undertaking.

Old Oak Common Depots’ electrical distribution is fed from a vast network of 6.6kV substations (B5, B1, T, S, D and E) in the form of a ring main derived from an 11kV Scottish and Southern Energy (SSE) supply. The ring main is operated with a normally open point as two radial 6.6kV circuits of which the HV switching equipment was locally controlled/operated with no indication or operation control from the railway electrical control room.

The two traction 25kv OHL feeder cables originated from Kensal Green Feeder Station and terminated at structure J/05/125 in the Hex depot and were affected by the Stage 3 works, with both cables running in parallel for the entire length.

One of the two 25kV cables is a feeder cable carrying traction current from Kensal Green Feeder Station section KAGA/805/HV/L and terminated to the sealing end of structure J/05/125.

The other 25kV cable is a traction return cable from Kensal Green Return Current Bus Bar (RCBB) section KAGA/HV/805/N and terminated on spider plate SP/05/101.

This complex HV power arrangement, necessitated the need for alternative HV feeds for both the 6.6kv ring main and 25kv OHL HV circuits to enable continuous supply to the railway infrastructure while the diversions/slewing of the HV cables were also undertaken.

RJ Power Rail’s highly qualified substation level `A`, liaised closely with the substation maintainer, electrical control room and Scottish and Southern Energy, to produce a clear and defined sequence of HV switching operations, for both the 6.6kv ring main and the 25kv traction cables, which enabled a continuous high voltage supply to the operational railway whilst works were undertaken.

The Benefits

RJ Power Group’s collaborative working approach allowed seamless integration into Colas Rail’s S&C Alliance practices.

As a vastly experienced, multi discipline and High Voltage service provider, RJ Power Rail was able to call on its expert knowledge to provide consultation on design and delivery elements of the project.

This extended to best practice advice, following an unexpected cable outage at the project. RJ Power Rail’s project team organised and presented an HV awareness presentation to Colas Rail, advising on all necessary standards and applicable guidelines.